|

RCÔNG NGHỆ CÁCH MẠNG CAO VỚI MÁY PHÁT ĐIỆN MẠCH RẮN ĐÃ XUẤT HIỆN !!

Đây là chuỗi máy phát điện phát triển mới với công nghệ tiên tiến, tiết kiệm năng lượng hữu hiệu, tính ổn định cao trongcông nghiệp máy hàn ống.Hiện nay, máy của công ty Hisen thuộc loại hiệu quả nhất với chi phí năng lượng thấp trong thị trường máy hàn ống.Công suất từ 60KW đến 1000KW phù hợp với yêu cầu hoạt động của khách hàng.

|

Đầu ra |

Đầu ra

Sản lượng (kW) |

60 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

500 |

600 |

800 |

1000 |

|

Tần suất(kHz) |

60~400KHZ |

|

Đầu vào |

Điện áp(V) |

3Ø, 220/380/415/440V±10% , 50/60Hz |

|

Điện dung(kVA) |

Đầu ra(kW)÷ 0.9=Đầu vào(kW) Đầu ra(kW)X 1.3= Đầu vào(kVA) |

|

Nước làm

mát |

Tiêu chuẩn chung |

Áp lực nước 2.5~3.5kgf/cm2 Nhiệt độ nước 25~40℃ |

|

Dòng nước(L/m)

Đk lối nước vào/ra |

100 |

120 |

200 |

260 |

400 |

500 |

600 |

|

40A |

65A |

50A*2 |

65A*2 |

|

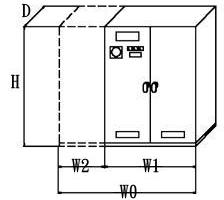

External

Dimensions |

Height H(mm) |

1750 |

2050 |

|

|

Inverter W1(mm) |

800 |

950 |

1150 |

1800 |

2300 |

3300 |

4300 |

|

Cooling system W2(mm) |

500 |

600 |

|

Total Width W0(mm) |

1300 |

1450 |

1650 |

2350 |

2800 |

3900 |

4900 |

|

Depth D(mm) |

950 |

1200 |

1500 |

|

Mass(kg) |

1600 |

1700 |

1900 |

2000 |

2200 |

2800 |

3000 |

3200 |

3400 |

3600 |

3800 |

4000 |

-

Cooling Water System with dual ratings:Lower rating is for

equipment with cooling water circulation while higher rating is for

equipment without cooling water circulation system.

-

Feel free to contact us for information on inverters with

other output capacities and frequencies not indicated in the above tables.

-

For product improvement, specifications and external

appearance are subject to change without notice.

Output |

Output

capacity (KW) |

100 |

200 |

300 |

400 |

500 |

600 |

800 |

1000 |

1200 |

1600 |

2000 |

Frequency(KHZ) |

1 ~ 50 KHZ |

Input |

Voltage(V) |

3Ø , 220/380/415/440 V± 10%

, 50/60 Hz

|

Capacity (KVA) |

Output(kW)÷0.9=Input(kW)

Output(kW)X 1.2=Input(kVA) |

Cooling

Water |

Common

specifications |

Water pressure 2.5 ~3.5kgf/cm2

Water temperature 25~40℃

|

Water flow(L/m)

Water

inlet/outlet dia |

30/40 |

60/80 |

85/110 |

100/130 |

120/160 |

140/190 |

230/300 |

275/300 |

340/440 |

500/650 |

520/680 |

20A |

25A |

40A |

40A/50A |

65A |

65A*2 |

80A*2 |

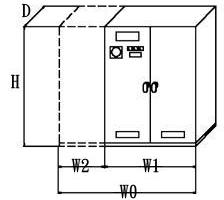

External

Dirnensions |

Height H(mm) |

1950 |

1950 |

1950 |

2350 |

2550 |

Inverter

W1(mm) |

800 |

650 |

1300 |

1600 |

1400 |

1700 |

2500 |

3500 |

5000 |

Cooling system

W0(mm) |

500 |

600 |

700 |

900 |

Total Width

W0(mm) |

1300 |

1550 |

1900 |

2300 |

2100 |

2400 |

3200 |

4200 |

5900 |

Depth D(mm) |

800 |

1000 |

1300 |

1200 |

1500 |

1200 |

Mass(kg) |

1200 |

1400 |

1700 |

1900 |

2400 |

3000 |

2600 |

3200 |

3800 |

6000 |

7200 |

-

Cooling Water System with dual ratings:Lower rating is for

equipment with cooling water circulation while higher rating is for

equipment without cooling water circulation system.

-

Feel free to contact us for information on inverters with

other output capacities and frequencies not indicated in the above tables.

-

For product improvement, specifications and external

appearance are subject to change without notice.

|

|

Product Features:

| 1. |

Total efficiency is greater than

90% |

| 2. |

Suitable for continuous long-time

production and steady output.

Increasing machine’s piece-rate

and the quality of the products. |

| 3. |

COMPACT DESIGN: Installation area

is only 600W*800D besides the

forming machine. The machine is

suitable to work with any tube

production lines. Replacing

oscillation tube type welders is

easy as position of forming

machine will not be affected.

|

| 4. |

Sensitive electrical parts are

safely closed inside the

electrical cabinet and far away

from the tube welding area. This

effectively increases the

machine’s life and decreases need

for repair. |

| 5. |

The input efficiency is greater

than 0.95 for any kinds of tube

size and output range. This

greatly reduces energy cost and

spending on peripheral equipments. |

| 6. |

EAST

MAINTENANCE AND INSPECTION. |

| 7. |

Dependable safety system:

◎protection

against abnormal water flow volume

◎protection

against abnormal water temperature

◎protection

against over voltage

◎protection

against over current

◎protection

against over frequency

◎protection

against low frequency

◎protection

against coil touch |

|

|

|

COMPARISON BETWEEN SOLID STATE

GENERATOR AND VACUUM TUBE GENERATORS:

|

1. |

INPUT

POWER CAN BE REDUCED 40%.

|

|

2. |

50%

REDUCTION IN WATER CONSUMPTION

|

|

3. |

50%

REDUCTION IN WATER FLOOR SPACE

|

|

4. |

60%

REDUCTION IN WATER TOTAL MASS

|

|

5. |

SERVICE

LIFE-

|

SOLID STATE GENERATOR: |

INFINITE |

|

VACUUM

TUBE OSCILLATOR: |

5,000~10,000

HOURS |

|

|

6. |

START

/ STOP-

|

SOLID STATE GENERATOR: |

MOMENTARY |

|

VACUUM

TUBE OSCILLATOR: |

PREHEAT

AND COOL TIME FOR FILAMENT |

|

|

7. |

OPERATION

COST-

|

SOLID STATE GENERATOR: |

LOWER

COST DUE TO HIGHER

EFFICIENCY AND LESS WATER |

|

VACUUM

TUBE OSCILLATOR: |

HIGHER

COST DUE TO LOWER

EFFICIENCY AND MORE WATER |

|

|

|